Abstract

Aim

To compare the quality and stability of unlicensed, repackaged bevacizumab intended for intravitreal injection, as provided by five licensed compounding pharmacies in the United Kingdom, with bevacizumab in its original glass vial.

Methods

Repackaged bevacizumab was obtained from five UK suppliers. Samples were analyzed at two time points (day 1 and day 14). Microflow imaging was performed to evaluate subvisible particle size, particle density, and particle size distribution. Protein concentration, immunoglobulin G (IgG) content, and molecular weight were also determined.

Results

A significant difference in subvisible particle density was observed between bevacizumab batches from the five suppliers on day 1 (P<0.001). An increase in subvisible particle density was observed between day 1 and 14 for repackaged bevacizumab from all suppliers (all P<0.05), but not the reference compound. Protein concentration, IgG content, and molecular weight were comparable between batches from each supplier and the reference bevacizumab.

Discussion

The study results indicate that the quality of bevacizumab repackaged into prefilled plastic syringes is variable among the different compounding pharmacies in the United Kingdom. Furthermore, particle density may increase with storage in repackaged syringes. It is noteworthy that particle size distribution in both the repackaged and reference bevacizumab fell outside of the range specified by the United States Pharmacopeia for injectable ophthalmic solutions. These data highlight the need for further research into the use of unlicensed, repackaged bevacizumab intended for intravitreal injection.

Similar content being viewed by others

Introduction

Bevacizumab (Avastin (Genentech, South San Francisco, CA, USA and Roche, Basel, Switzerland)) is a full-length, 149 kDa, humanized monoclonal antibody that inhibits vascular endothelial growth factor (VEGF). Bevacizumab is approved by the Food and Drug Administration and European Medicines Agency for the intravenous treatment of metastatic colorectal cancer, non-small cell lung cancer, metastatic renal cell cancer, and glioblastoma.1 However, it is often used unlicensed as an intravitreal injection for the treatment of wet age-related macular degeneration (AMD), diabetic macular edema, and macular edema following retinal vein occlusion. When used for these indications, bevacizumab is frequently repackaged from large, glass vials into multiple, smaller, single-use, plastic, prefilled syringes. This is because repackaged bevacizumab is notably less expensive than ranibizumab (Lucentis (Novartis, Basel, Switzerland and Genentech/Roche)), a humanized, monoclonal anti-VEGF antigen-binding fragment (Fab, 48 kDa) derived from the same original mouse antibody as bevacizumab, but which is licensed for the treatment of retinal diseases.2

Several publications have suggested that unlicensed intravitreal bevacizumab is efficacious in the treatment of AMD,3, 4, 5 and that it has a similar ocular safety profile to ranibizumab.6, 7, 8 These publications include the 1- and 2-year reports from the comparison of AMD treatments trials, a randomized, single-masked, non-inferiority trial of intravitreal bevacizumab and ranibizumab in 1208 patients with wet AMD.5, 9 However, there are increasing reports of adverse events associated with intravitreal injection of bevacizumab, including incidences of intraocular sterile inflammation,10, 11, 12, 13, 14, 15 infectious endophthalmitis,11, 16 and elevated intraocular pressure.17, 18, 19, 20, 21 Certain reported adverse events associated with the intravitreal administration of bevacizumab may be related either to the intrinsic properties of the molecule and the manner in which it is manufactured, or to deterioration in the quality of the drug as a consequence of the repackaging into plastic syringes.22, 23

The pharmacopoeial standards for the manufacture of intravitreal injections are different from those for intravenous administration with respect to the amounts of subvisible particles permitted; visible particles are not permitted in intravenous or intravitreal preparations. The United States Pharmacopeia (USP) manufacturing requirements for intravenous drug formulations permit higher subvisible particulate counts than that for ophthalmic solutions.24, 25 Particulate matter may cause irritation and inflammation if injected into the eye.26, 27, 28

There is very little information available on the quality and stability of bevacizumab when repackaged for intraocular administration. A few recent reports from the United States have examined the quality of compounded bevacizumab repackaged into plastic syringes for intravitreal injection.22, 23 Changes in the immunoglobulin G (IgG) content, the presence of silicone oil microdroplets, and protein aggregation associated with repackaging were reported.22, 23 Deterioration may also be subject to the particular packaging used,23 and reduced stability of repackaged bevacizumab may be associated with duration of storage.22, 29 In addition to the potential safety implications of these changes, the efficacy of the drug may also be affected.23

In the United Kingdom, prefilled syringes of bevacizumab are manufactured in approved Medicines and Healthcare products Regulatory Agency compounding units. However, the procedures for the manufacturing and quality/stability tests for these unlicensed repackaged products are not clear. The aims of this study were to assess the quality and stability of repackaged bevacizumab in prefilled plastic syringes obtained from five compounding pharmacies in the United Kingdom, and bevacizumab in its original glass vial, to investigate changes in the quality of repackaged bevacizumab over time, and to investigate the possible differences in the quality of bevacizumab batches obtained from the same supplier and between different suppliers. Possible bacterial and endotoxin contamination of the samples was not investigated in this study.

Materials and methods

Study design

The quality and stability of repackaged bevacizumab from five UK compounding pharmacies (S1–S5) were assessed at two time points, 14 days apart (day 1 and day 14), and compared with a control solution of bevacizumab in its original glass vial. The parameters measured in order to assess bevacizumab quality and stability included subvisible particle size, particle density, total protein content, IgG content, and molecular weight.

Bevacizumab formulations

Between two and five different batches of plastic syringes containing bevacizumab, repackaged using standard procedures were received from five UK suppliers between 18 October and 30 November 2011. A sample of bevacizumab in its original single-use glass vial was received with the first batch of syringes and was used as the reference compound. The reference bevacizumab glass vial and repackaged bevacizumab syringes were purchased through standard commercial channels by Nottingham University. The samples were transported to Newcastle University at 4 °C in appropriate temperature-controlled vehicles by a commercial pharmaceutical logistics company.

Experimental procedures

All samples were stored at 4 °C and evaluations were performed on the day following receipt of the sample, and within the set shelf-life of 90 days stipulated by the suppliers of repackaged bevacizumab. Measurements were performed at room temperature.

MFI: subvisible particles

Microflow imaging (MFI) was used to quantify aggregates and particulates. Particle size and particle density/concentration were measured. For each batch, samples pooled from the five plastic syringes were diluted 30-fold with 0.2 μm filtered bevacizumab placebo (50 mmol/l sodium phosphate, pH 6.25, 60 mg/ml α,α-trehalose dihydrate, 0.4 mg/ml polysorbate 20) replicating the product formulation, and injected into the MFI flow cell (DPA 5100, ProteinSimple, Ottawa, ON, Canada). Control measurements were calculated for the reference solution of bevacizumab. Further analysis of particle size distribution was performed on all samples. On the basis of a previous method developed for classifying oil vs non-oil particles,30 digital filtering of particles >5 μm diameter was carried out using the MFI View Analysis Suite Filter Manager software (ProteinSimple). Filters used were based on a combination of three image parameters that allowed silicone oil droplets to be distinguished from other particles: equivalent circular diameter (>5 μm), circularity (>0.75 μm), and aspect ratio (>0.90 μm).

Protein content

Total protein content of the syringes and reference bevacizumab was determined using the Coomassie Plus (Bradford31) Assay Kit (Pierce/Thermo Scientific, Rockford, IL, USA). Bevacizumab preparations (25 mg/ml) were diluted 1 : 40 in phosphate-buffered saline (PBS) before addition of the assay reagent. Absorbance was measured at 595 nm. Protein concentrations were determined from a standard curve prepared from a serial dilution of purified human IgG (Pierce/Thermo Scientific). For each syringe, bevacizumab protein content was determined based on an average of triplicate samples.

Immunoglobulin content

Total IgG concentrations were determined using the Easy-Titer Human IgG (H+L) Assay Kit (Pierce/Thermo Scientific). Bevacizumab preparations were diluted 1 : 2 × 105 in PBS. Following incubation with antibody-coated microspheres, absorbance was measured at 405 nm. IgG concentrations were determined from a standard curve prepared from a serial dilution of purified human IgG. For each syringe, IgG content was determined based on an average of triplicate samples.

Polyacrylamide gel electrophoresis

Protein molecular weight was determined by SDS-polyacrylamide gel electrophoresis (PAGE).32 Bevacizumab samples were prepared in Laemmli SDS sample buffer, with or without dithiothreitol as a reducing agent, and heated to 70 °C for 10 min before loading on a 10% SDS-polyacrylamide gel using a Tris/Glycine running buffer. For each sample, 4 μg was loaded and gels were run for 30 min at 40 mA. Gels were stained with Coomassie Blue R-250 (Sigma-Aldrich, Gillingham, UK) and subsequently destained to visualize protein bands.

Size-exclusion chromatography

Levels of monomers and soluble protein aggregates of bevacizumab in the repackaged samples were determined by size-exclusion high-performance liquid chromatography (SE-HPLC). The samples were diluted to 500 μg/ml in PBS, and 100 μl was injected onto a size-exclusion column (TSK-GEL G3000SWxl, Supelco HPLC Columns, Sigma-Aldrich), previously equilibrated with PBS. Protein elution was monitored at 280 nm with an ultraviolet absorbance detector. Protein standards were used as size references.

Statistical analysis

Minitab statistical software (version 15.5; Coventry, UK) was used for the statistical analysis of data. Data were tested for normality. Data were analyzed using Student’s t-test and analysis of variance as appropriate. A P-value of <0.05 was considered statistically significant. Data are presented as mean±SD, unless otherwise stated. For comparison between suppliers, data from a representative batch from each compounding pharmacy were used. More than one batch was received from each supplier to allow for comparisons between batches from the same supplier.

Results

In total, four batches of syringes were received from S1 and two batches were received from each of S2–S5 between 18 October and 30 November, 2011. Each batch contained five syringes.

MFI: subvisible particles

A significant difference was observed in subvisible particle density (particles/ml) on day 1 between representative batches from the five suppliers (P<0.001; Table 1). Similarly, significant differences were seen when comparing particle density on day 1 with all of the batches received from a single supplier (P<0.001 for all suppliers, data not shown). There were significant increases in subvisible particle density between day 1 and day 14 for repackaged bevacizumab from all of the suppliers (all P<0.05), but not for the reference bevacizumab (Table 1).

There were no significant differences in mean particle size on day 1 between the representative batches from the five suppliers; however, significant differences in particle size were observed by day 14 (P<0.001; Table 2). There was a significant decrease in mean particle size by day 14 for the representative batch from S2 (P<0.05). In contrast, an increase in mean particle size was observed over this time for the batch from S3 (P<0.05; Table 2).

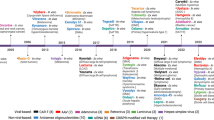

Analysis of the particle size distribution for all samples (S1–S5) and the reference bevacizumab revealed that, in general, the number of subvisible particles between 10 and 24 μm in size increased between days 1 and 14, with the exception of the sample from S4 (Figure 1a). Similarly, there was a general increase in the number of larger subvisible particles (25–50 μm), with the exception of the sample from S2 (Figure 1b). It was also noted that visible particles (>50 μm) were present to varying degrees in samples from S1–S5 at days 1 and 14 (S1, 42 vs 21; S2, 0 vs 21; S3, 21 vs 0; S4, 0 vs 21 and S5, 42 vs 84, mean particles/ml at day 1 and day 14, respectively). Visible particles were not detected in the reference bevacizumab at either time points.

Subvisible particle size distribution for particles (a) 10–24 μm and (b) 25–50 μm, and (c) the percentage of total particles that are silicone in all samples from each supplier (S1–S5) and reference bevacizumab. S1–S5, samples from suppliers S1–S5. P-values are based on a Student’s t-test and analysis of variance and compared measurements of a representative batch from a single supplier at day 1 and day 14.

Application of digital filtering parameters identified silicone-derived particles in all samples (S1–S5), including the reference bevacizumab, which accounted for between 1.6 and 12.3% of all particles over 5 μm (Figure 1c). No significant change in the percentage of silicone particles was observed between day 1 and day 14 for the bevacizumab reference sample or samples from S1, S2, S4, and S5. A significant increase (P<0.001) in silicone particles was observed between day 1 and day 14 for samples from S3 (day 1, 6.3% vs day 14, 12.3%; Figure 1c).

Protein concentration

Overall, when independently comparing the individual samples of repackaged bevacizumab received from each supplier (S1–S5) with the reference bevacizumab, protein concentration was similar on day 1 and day 14 (Table 3). However, in an analysis of representative batches received from each supplier, there was a significant difference in total protein concentration between batches from all suppliers at day 1 (P<0.0001). This difference was attributed to an anomaly as the representative batch from one supplier (S1) demonstrated a lower protein concentration at day 1 compared with the samples obtained from S2–S5. There were no significant differences in protein concentration observed between representative batches from the five suppliers at day 14.

Immunoglobulin content

The IgG content was similar in the repackaged representative batches and the reference bevacizumab sample on day 1 and day 14. Significant differences were observed in IgG concentration between the different batches received from S1 to S5 at day 1 (P<0.001; data not shown). When IgG concentrations at day 1 were determined for representative samples obtained from all five suppliers, no significant differences between suppliers were observed. There were no significant inter-batch differences in IgG concentration between the samples from each supplier, or the reference bevacizumab, between day 1 and day 14 (data not shown).

Polyacrylamide gel electrophoresis

When repackaged bevacizumab from each of the five suppliers and reference bevacizumab were analyzed using SDS-PAGE, similar results were observed for each sample at both time points. Under nonreducing conditions, a band representing IgG was visible in each of the samples at ∼150 kDa. When SDS-PAGE was performed under reducing conditions (in the presence of dithiothreitol), two bands were visible representing the heavy (∼55 kDa) and light chains of IgG (∼25 kDa; Figure 2).

Size-exclusion chromatography

There were no detectable differences in levels of bevacizumab monomers or protein aggregates observed between any of the samples obtained from the five compounding pharmacies, or the reference bevacizumab, when samples were compared using SE-HPLC at day 1 and day 14 (data not shown).

Discussion

There have been a number of reports of sterile endophthalmitis after intravitreal injection of compounded bevacizumab.10, 11, 12, 13, 15 This, combined with further reports of infectious endophthalmitis, led to the practice of repackaging bevacizumab from sterile glass vials into plastic syringes being brought into question.15, 33 The present study was designed to investigate the quality and stability of repackaged bevacizumab obtained from five licensed compounding pharmacies in the United Kingdom, compared with the drug in its original glass vial, over a period of 14 days, and to assess the possible differences in the quality of bevacizumab between different batches from the same supplier and between the different suppliers.

The results of this study demonstrated that there were overall differences in the composition of repackaged bevacizumab obtained from the five UK compounding pharmacies, and between repackaged and reference bevacizumab. When assessing the quality of repackaged bevacizumab compared with the reference bevacizumab in its original vial, the results of MFI, and changes in subvisible particle size distribution, were of particular note. Significant differences in subvisible particle density were observed between representative samples from the five suppliers at day 1 and day 14, indicating that repackaged bevacizumab from different compounding pharmacies may differ in composition and quality. Furthermore, when batches received from the individual suppliers were examined independently on day 1, significant differences were observed in subvisible particle density, suggesting that even bevacizumab repackaged into syringes from the same original vial by the same pharmacy can demonstrate marked variation in the quality and composition. The compounded bevacizumab from each of the five suppliers demonstrated a significant increase in subvisible particle density over time, an increase that was not observed for the reference bevacizumab. Analysis of the particle size distribution for all samples (S1–S5) revealed that the number of medium (10–24 μm) and larger (25–50 μm) particles generally increased over the study period. It was noted that, in several of the samples for which particle size distribution analyses were performed, particulates >50 μm (visible) were detected. Interestingly, there was no significant change in the proportion of these particles identified as silicone oil droplets over the study period in the majority of samples or the reference bevacizumab sample, indicating that silicone oil was not the source of the significant increase in particulate matter in these samples over the 14 days. The variations in particle numbers between samples may be related to the detailed compounding process, repackaging, or to the different types of plastic syringe and closures used by each compounding pharmacy.

It is noteworthy that particle size distribution for all of the samples and the reference bevacizumab fell outside of the acceptable USP standard range for ophthalmic injectable products25 at both day 1 and day 14. This demonstrated that, even in its original packaging, bevacizumab does not conform to the limits for ophthalmic solutions. Supporting the observations of Liu et al,22 a wide range of particle counts were observed between repackaged bevacizumab from different compounding pharmacies. There were ∼14 times more subvisible particles found at day 1 in the sample from S3 than the reference bevacizumab, whereas the sample from S2 contained a similar number of particles to the reference compound. This further indicates the potential for variation in repackaged bevacizumab. Interestingly, the particle count for the reference bevacizumab in the current study was less than that observed in a similar study by Liu et al.22 It was further observed that the highest subvisible particle count was for the sample with the oldest shelf-life at the time of testing (S3: day 1, 69 days; day 14, 83 days), although this was still within the shelf-life of 90 days. This sample also displayed a significant increase in silicone oil droplets over the study time period. The implication of this result is unclear from this single analysis. It is acknowledged that the subvisible particle testing technique performed in this analysis is not as stipulated by the USP; however, the MFI technique has been well described previously,34 and is frequently used within the pharmaceutical industry to examine particle contamination in therapeutic protein products.

Data from previous studies suggest that subvisible and visible particulates may be silicone oil,22, 35 particulate matter from the syringes and syringe closures,23 or a result of protein aggregation.23, 34 The lack of significant difference observed in the silicone oil levels, SE-HPLC, and SDS-PAGE between samples from the five suppliers or the reference bevacizumab suggests that the increase in particle counts was not due to irreversibly bound protein aggregates or silicone oil droplets. It is more likely due to reversible protein aggregation or the presence of non-protein particulates. However, as suggested by Kahook et al,23 size-exclusion chromatography and PAGE are unlikely to demonstrate sufficient sensitivity to detect these particles. Further investigations are necessary to repeat these analyses and to characterize the particulates found within the prefilled syringes.

The increase in particulate matter observed over time in the repackaged bevacizumab may have implications for the safety profile of this unlicensed formulation, especially when used for intravitreal injection after compounding and storage. Particulate matter may be a contributing factor in some of the recent reports of clusters of intraocular inflammation after intravitreal injection of bevacizumab for the treatment of AMD.

Licensed ranibizumab and pegaptanib for intravitreal injection have been assessed for product quality and stability over their 3-year shelf lives, are approved by US and European regulatory authorities, and meet all required pharmaceutical standards and recommendations for use. In contrast, repackaged, unlicensed bevacizumab in plastic, prefilled syringes are not currently similarly assessed. The results of our study indicate that the quality of bevacizumab supplied in prefilled plastic syringes for intravitreal injection may be affected over time. The observed increase in particulate matter in these samples of repackaged bevacizumab does not support the suggested 3-month stability. Further studies are needed to ascertain the full extent of any deterioration in the quality and stability of the product during the stipulated shelf-life of 90 days.

The data presented in this study support those from other similar studies of repackaged bevacizumab,22 and highlight the need for further research into the quality and stability of unlicensed bevacizumab for intravitreal injection.

References

Genentech. Avastin. Summary of product characteristics. January 2010. Available at http://www.ema.europa.eu/docs/en_GB/document_library/EPAR_-_Product_Information/human/000582/WC500029271.pdf. (accessed July 2012).

Novartis. Lucentis summary of product characteristics. January 2012. Available at http://www.medicines.org.uk/emc/history/19409/SPC/Lucentis+10+mg+ml+solution+for+injection. (accessed July 2012).

Rich RM, Rosenfeld PJ, Puliafito CA, Dubovy SR, Davis JL, Flynn HW Jr et al. Short-term safety and efficacy of intravitreal bevacizumab (Avastin) for neovascular age-related macular degeneration. Retina 2006; 26: 495–511.

Martin DF, Maguire MG, Ying GS, Grunwald JE, Fine SL, Jaffe GJ . Ranibizumab and bevacizumab for neovascular age-related macular degeneration. N Engl J Med 2011; 364: 1897–1908.

Chakravarthy U, Harding SP, Rogers CA, Downes SM, Lotery AJ, Wordsworth S et al. Ranibizumab versus bevacizumab to treat neovascular age-related macular degeneration. Ophthalmology 2012; 119: 1399–1411.

Jyothi S, Chowdhury H, Elagouz M, Sivaprasad S . Intravitreal bevacizumab (Avastin) for age-related macular degeneration: a critical analysis of literature. Eye 2009; 24: 816–824.

Manzano RP, Peyman GA, Khan P, Kivilcim M . Testing intravitreal toxicity of bevacizumab (Avastin). Retina 2006; 26: 257–261.

Chang TS, Kokame G, Casey R, Prenner J, Feiner L, Anderson N . Short-term effectiveness of intravitreal bevacizumab versus ranibizumab injections for patients with neovascular age-related macular degeneration. Retina 2009; 29: 1235–1241.

Martin DF, Maguire MG, Fine SL, Ying GS, Jaffe GJ, Grunwald JE et al. Ranibizumab and bevacizumab for treatment of neovascular age-related macular degeneration: two-year results. Ophthalmology 2012; 119: 1388–1398.

Bakri SJ, Larson TA, Edwards AO . Intraocular inflammation following intravitreal injection of bevacizumab. Graefes Arch Clin Exp Ophthalmol 2008; 246: 779–781.

Artunay O, Yuzbasioglu E, Rasier R, Sengul A, Bahcecioglu H . Incidence and management of acute endophthalmitis after intravitreal bevacizumab (Avastin) injection. Eye 2009; 23: 2187–2193.

Yamashiro K, Tsujikawa A, Miyamoto K, Oh H, Otani A, Tamuara H et al. Sterile endophthalmitis after intravitreal injection of bevacizumab obtained from a single batch. Retina 2010; 30: 485–490.

Kay CN, Tarantola RM, Gehrs KM, Folk JC, Mahajan VB, Boldt HC et al. Uveitis following intravitreal bevacizumab: a non-infectious cluster. Ophthalmic Surg Lasers Imaging 2011; 42: 292–296.

Ness T, Feltgen N, Agostini H, Bohringer D, Lubrich B . Toxic vitreitis outbreak after intravitreal injection. Retina 2010; 30: 332–338.

Medicines and Healthcare products Regulatory Agency 2012 Company-led drug recall: Bevacizumab Intravitreal Injection 1.25mg/0.05ml—Moorfields Pharmaceuticals—CLDA(12)A/04 http://www.mhra.gov.uk/Safetyinformation/Safetywarningsalertsandrecalls/DrugAlerts/Company-ledrecalls/CON146660. (accessed 15 March).

Goldberg RA, Flynn HW Jr., Isom RF, Miller D, Gonzalez S . An outbreak of streptococcus endophthalmitis after intravitreal injection of bevacizumab. Am J Ophthalmol 2012; 153: 204–208 e1.

Good TJ, Kimura AE, Mandava N, Kahook MY . Sustained elevation of intraocular pressure after intravitreal injections of anti-VEGF agents. Br J Ophthalmol 2011; 95: 1111–1114.

Jalil A, Fenerty C, Charles S . Intravitreal bevacizumab (Avastin) causing acute glaucoma: an unreported complication. Eye 2007; 21: 1541.

Kahook MY, Kimura AE, Wong LJ, Ammar DA, Maycotte MA, Mandava N . Sustained elevation in intraocular pressure associated with intravitreal bevacizumab injections. Ophthalmic Surg Lasers Imaging 2009; 40: 293–295.

Adelman RA, Zheng Q, Mayer HR . Persistent ocular hypertension following intravitreal bevacizumab and ranibizumab injections. J Ocul Pharmacol Ther 2010; 26: 105–110.

Choi DY, Ortube MC, McCannel CA, Sarraf D, Hubschman JP, McCannel TA et al. Sustained elevated intraocular pressures after intravitreal injection of bevacizumab, ranibizumab, and pegaptanib. Retina 2011; 31: 1028–1035.

Liu L, Ammar DA, Ross L, Mandava N, Kahook M, Carpenter J . Silicone oil microdroplets and protein aggregates in repackaged bevacizumab and ranibizumab: effects of long-term storage and product mishandling. Invest Ophthalmol Vis Sci 2011; 52: 1023–1034.

Kahook MY, Liu L, Ruzycki P, Mandava N, Carpenter JF, Petrash JM et al. High-molecular-weight aggregates in repackaged bevacizumab. Retina 2010; 30: 887–892.

Particulate Matter in Injections,. USP 28/NF 23, Chapter 788 United States Pharmacopeial Convention, Inc: Rockville, MD, 2005.

Costa R . Particulate Matter in Ophthalmic Solutions,. USP 28/NF 23, Chapter 789 United States Pharmacopeial Convention, Inc.: Rockville, MD, 2005.

Weber AJ, Zelenak D . Experimental glaucoma in the primate induced by latex microspheres. J Neurosci Methods 2001; 111: 39–48.

Urcola JH, Hernandez M, Vecino E . Three experimental glaucoma models in rats: comparison of the effects of intraocular pressure elevation on retinal ganglion cell size and death. Exp Eye Res 2006; 83: 429–437.

Quigley HA, Addicks EM . Chronic experimental glaucoma in primates. I. Production of elevated intraocular pressure by anterior chamber injection of autologous ghost red blood cells. Invest Ophthalmol Vis Sci 1980; 19: 126–136.

Bakri SJ, Snyder MR, Pulido JS, McCannel CA, Weiss WT, Singh RJ . Six-month stability of bevacizumab (Avastin) binding to vascular endothelial growth factor after withdrawal into a syringe and refrigeration or freezing. Retina 2006; 26: 519–522.

Strehl R, Rombach-Riegraf V, Diez M, Egodage K, Bluemel M, Jeschke M et al. Discrimination between silicone oil droplets and protein aggregates in biopharmaceuticals: a novel multiparametric image filter for sub-visible particles in microflow imaging analysis. Pharm Res 2012; 29: 594–602.

Bradford MM . A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 1976; 72: 248–254.

Laemmli UK, Favre M . Maturation of the head of bacteriophage T4. I. DNA packaging events. J Mol Biol 1973; 80: 575–599.

FDA alerts health care professionals of infection risk from repackaged Avastin intravitreal injections. 30 August 2011 http://www.fda.gov/Drugs/DrugSafety/ucm270296.htm. (accessed July 2012).

Carpenter JF, Randolph TW, Jiskoot W, Crommelin DJ, Middaugh CR, Winter G et al. Overlooking subvisible particles in therapeutic protein products: gaps that may compromise product quality. J Pharm Sci 2009; 98: 1201–1205.

Paul M, Vieillard V, Roumi E, Cauvin A, Despiau MC, Laurent M et al. Long-term stability of bevacizumab repackaged in 1mL polypropylene syringes for intravitreal administration. Ann Pharm Fr 2012; 70: 139–154.

Acknowledgements

This study was supported by Novartis Pharmaceuticals UK Limited. Medical writing support was provided by Fishawack Communications Ltd., Oxford, United Kingdom, and funded by Novartis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

JMP and FK received a grant from Novartis for this research. WMA has received travel grants from Novartis and Allergan, has participated in clinical trials sponsored by Novartis and Pfizer and has participated in advisory boards for, and received honoraria from, Bayer, Novartis, Allergan and Thrombogenics. WMA’s institution (University of Nottingham) has received research grants from Allergan and Novartis.

Rights and permissions

About this article

Cite this article

Palmer, J., Amoaku, W. & Kamali, F. Quality of bevacizumab compounded for intravitreal administration. Eye 27, 1090–1097 (2013). https://doi.org/10.1038/eye.2013.139

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/eye.2013.139

Keywords

This article is cited by

-

Storage stability of bevacizumab in polycarbonate and polypropylene syringes

Eye (2015)

-

Prevention and treatment of injection-related endophthalmitis

Graefe's Archive for Clinical and Experimental Ophthalmology (2014)